- Fast construction and production

- Clean construction site

- The most popular method of wood construction

Technology

The wooden frame house construction technology is the combination of a centuries-long tradition and modern solutions. It is a traditional and, at the same time, modern method of construction.

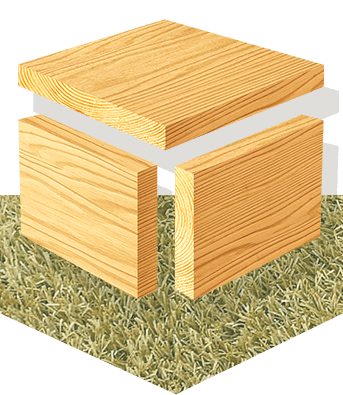

The basic structure of the building is a wooden frame filled with a thermal insulation material. The construction of a wooden frame allows for a wide range of choices of thermal insulation materials (stone wool, wood fibre wool, eco-wool, etc.) and the selection of finishing materials (decoration boards, decorative plaster, facade bricks, plastic trim boards, etc.).

Wooden frame buildings are known for fast assembly. Depending on the layout of the building, assembly of a wooden frame house at the construction site can take up to 3 days. If the foundations of a building are laid before the ground has frozen, the building can be assembled in the winter.

The panels of wooden frame buildings are industrially manufactured at a factory, ensuring their high precision and quality. During production, the building is covered by a roof to protect it from the risk of changing weather conditions. Panels are produced according to precise computerised designs, so high precision is guaranteed and the effects of human error are reduced.

Contrary to popular belief, wooden frame structures are not short-lived or intended for temporary buildings. Many of the architectural monuments throughout Riga and Latvia prove the longevity of wooden houses. Wood is a competitive construction material and has proven its durability and ecological benefits over the years.

Reviews